Know More About Triplett Electrical Continuity Testers

What is the Importance of Continuity Testing in Electrical Work?

Continuity testing is performed on electrical circuits to check their ability to conduct current. This process is vital as it directly contributes to electrical systems' safety, functionality, and reliability. Here is a closer look at why continuity testing is so important:

- Helps Identify faults:When an electrical system fails or malfunctions, continuity testing is a quick and effective way to pinpoint the source of the problem. By systematically checking each part of the circuit, electricians can identify where the break or fault occurs, making repairs more efficient.

- Long-term performance:Continual testing enhances the overall reliability of electrical systems by ensuring that all connections and components are correctly installed and functioning. This will prevent breakdowns and offer a longer lifespan for the equipment.

- Functional assurance:Any electrical device or installation must have a complete circuit to function correctly. Continuity testing verifies that all connections are intact, ensuring the current can flow as intended.

- Helps avoid electrical hazards:Continuity testing helps find open circuits, shorts, and poor connections. These issues can be dangerous if not addressed on time. We can easily prevent electrical shocks, fires, and other hazards in time by finding and fixing these issues before turning on the circuit.

- Ensure quality control:Continuity testing is essential for quality control in manufacturing and installation. It ensures that all products and installations meet the required electrical standards and specifications, guaranteeing their reliability and safety.

How to Use Digital Multimeters as Electrical Continuity Meters?

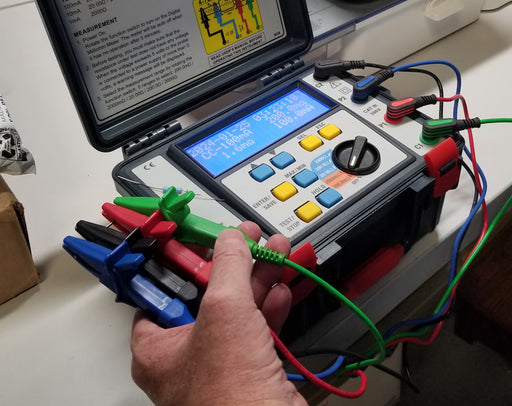

A digital multimeter is a flexible tool that measures several electrical properties, such as voltage, current, and resistance. One of its essential functions is testing electrical continuity. Here's a complete breakdown of using DMM as an electrical continuity meter.

Step 1: Check for the Safety:

- In this step, you need to check for safety first. To do that, make sure the power to the circuit you're testing is turned off to avoid any risk of electric shock or damaging the multimeter.

- If you are testing within a circuit containing capacitors, ensure they are fully discharged.

Step 2: Multimeter Set-Up:

- Now, set your multimeter to the continuity test mode. This is usually indicated by a symbol resembling a sound wave or a diode. In continuity mode, the multimeter typically emits an audible beep if the circuit is complete.

- Next, plug the black probe into the common (COM) jack and the red probe into the voltage (V) jack.

Step 3: Continuity Testing

- It's time to check the multimeter, but before testing the actual circuit, touch the probe tips together. The multimeter should emit a continuous beep showing it is functioning correctly.

- Now, place the probe tips on either side of the component or section of the circuit you wish to test.

- When testing, maintain good contact with the terminals or conductors. This reduces the risk of false results.

Step 4: Results Evaluation

- If you notice that multimeter is beeping continuously, it means the circuit is complete and current can flow through it.

- If you don't hear a beep, this indicates an open circuit, which means there is a break or fault, and the current cannot flow.

Applications of Electrical Continuity Testers

Continuity testers offer valuable assistance to professionals and DIY enthusiasts who use them for

- Safety Checks: Safety is essential when it comes to electrical systems, and that's where continuity testers come into play. They ensure safe operations by verifying proper groundings, which prevents electrical hazards such as electric shocks. These testers are used to check the reliability of grounding systems in residential and commercial applications. This helps prevent accidents and avoid hazards that may endanger lives of people using them.

- Addressing Faults: Continuity testers are valuable assets when troubleshooting electrical systems. They help address faults like interruptions, breaks, or discontinuities within circuits. For example, in homes, these tools are used to find problems with lights or outlets. In factories, they help identify issues with machinery connections, reducing downtime and keeping things running smoothly.

- Electrical Device Testing: Various appliances and devices have complex internal wiring and components. Continuity testers help verify these internal connections are intact and functioning correctly, ensuring that the appliance will operate as intended. Some individual components like resistors, switches, and fuses can be tested for continuity to ensure they are not damaged and perform their roles within the circuit.

- Quality Control: Continuity testers also helps in maintaining high-quality electrical connections. They ensure the proper connection of wires and components and electricity conduction without interruptions. By verifying the quality of electrical connections, these testers make sure that electrical systems help ensure reliability and durability of electric circuits.

How to Choose the Right Electrical Continuity Tester for Your Application?

When it comes to choosing the right electrical continuity tester, you must consider some important factors. In this section, we will discuss those crucial factors:

1. Ease of Use:

- It's important for a tester to have an easy-to-use interface and a clear display. This makes it easier to understand and reduces the chance of errors.

- Consider testers with ergonomic designs that provide a comfortable grip for better handling, especially for extended periods.

2. Portability:

- If you are a professional who needs to carry tools to various job sites, look for a lightweight and compact tester as it enhances convenience and efficiency.

- Look for models with protective cases or holders, ensuring the tester is easy to transport and remains undamaged.

3. Additional Functionalities:

Here are some additional functionalities that you can look for while choosing the one:

- Audible Alerts: This feature can quickly indicate continuity, allowing for faster and more efficient testing, especially in noisy environments.

- Auto Power-Off: This feature helps conserve battery life, ensuring that the tester is ready for use whenever needed.

- Backlight Display: A backlit display can be beneficial in low-light conditions, ensuring the readings are always visible.

How to Maintain and Calibrate Your Electrical Continuity Testers?

Maintaining and calibrating your electrical continuity testers is essential for ensuring their accuracy, reliability, and longevity. Here are some steps and best practices that will help you keep your continuity testers in optimal condition.

Maintenance Tips:

Here are some maintenance tips you need to consider for the continuity testers:

- Regular Cleaning: Keep the tester clean by wiping it with a soft, dry cloth. Avoid harsh chemicals. Clean the probes regularly with fine-grit sandpaper or a contact cleaner for good contact.

- Damage Inspection: Inspect the tester for physical damage, such as cracks or broken parts. Check the probe wires for cuts, frays, or damage that could affect performance.

- Battery Care: Check the battery level regularly and replace it as needed to maintain accuracy. Remove the batteries if the tester is not being used for a long time to prevent leakage and corrosion.

- Proper Storage: Store the tester in a dry, cool place to avoid exposure to moisture and extreme temperatures. Use a protective case to prevent physical damage when not in use.

Calibration Process:

Here's how to calibrate your tester:

- Follow the Manufacturer's Instructions: Always follow the calibration instructions described in the user manual offered with the tester. Manufacturers often recommend calibrating annually, but the frequency can vary based on usage.

- Utilize Known References: To ensure accuracy, use precision resistors to check your tester's readings against known values. For more precise calibration, utilize a calibration source or a specialized calibrator for electrical testing equipment.

- Zero Adjustments: Connect the probes together and ensure the tester reads zero ohms. If not, adjust the tester as per the manufacturer's instructions to achieve a zero reading.